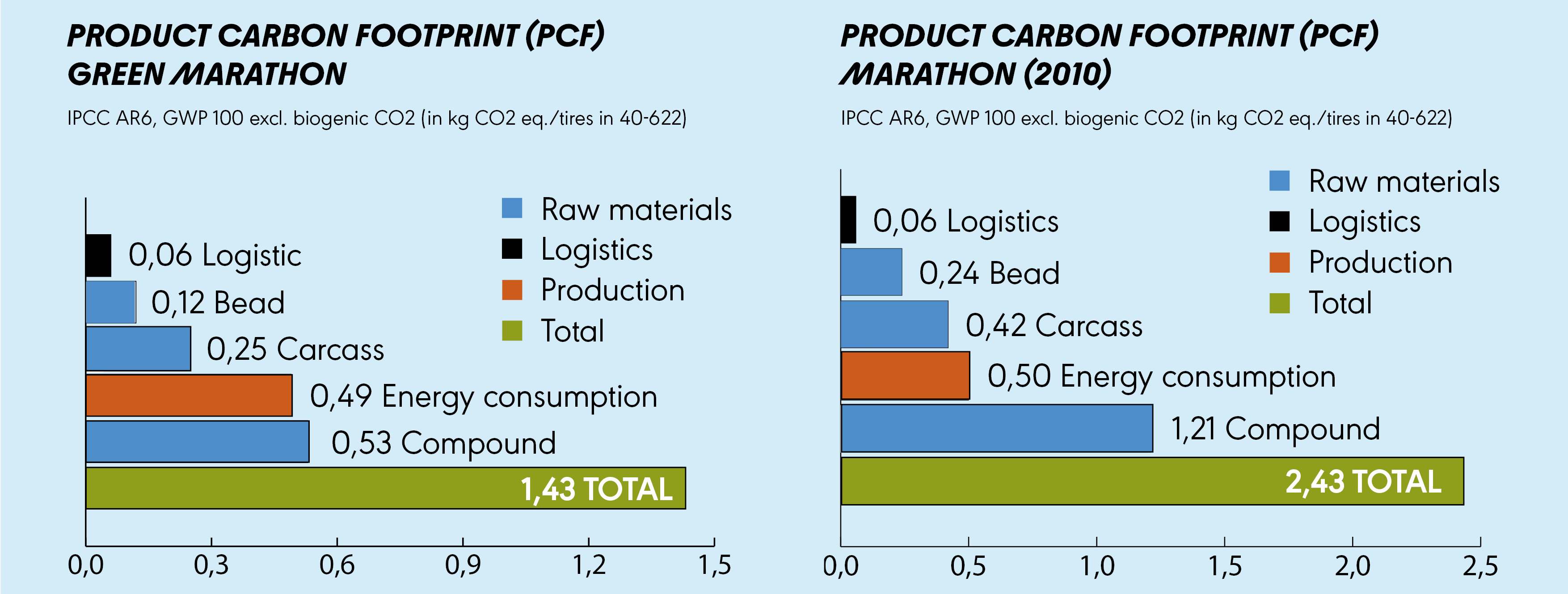

The production of the new Marathon saves more than one third of CO2 compared to the previous model, about 34% CO2. To determine the CO2 savings, a detailed Product Carbon Footprint (PCF) of both models was calculated and evaluated according to the common IPCC AR6 standard (GWP 100, excl. biogenic CO2).

THE GREEN MARATHON IS THE FIRST BICYCLE TIRE

WITH A CLOSED-LOOP PRODUCT CYCLE.

Made from 100% Fair Rubber.

And 80% from recycled and renewable raw materials.

Reduced pollutants by 99%.

And 41% reduced CO2eq footprint. Learn more about the detailed life cycle assessment

All the above with optimized riding performance and all of the durability associated with the previous Marathon.

THE GREEN MARATHON: New Responsibility - Same Reliability

WELCOME TO A NEW CYCLING MOVEMENT.

CREATED FOR A NEW GENERATION OF ENVIRONMENTALLY

ENGAGED CYCLISTS. WHO WANT TO TRAVEL THE EARTH MORE GENTLY.

UNITED BY OUR LOVE OF CYCLING. AND OUR COMMITMENT

TO ENVIRONMENTAL AND SOCIAL RESPONSIBILITY.

JOIN THE RECYCLISTS AND LET’S RIDE TOGETHER TOWARDS A BETTER FUTURE.

Life Cycle Assessment for Green Marathon:

Schwalbe has now presented a detailed Life Cycle Assessment (LCA) to quantify the environmental impact of the Green Marathon. The result: With 1.43 kg CO2 equivalents (CO2eq)*, the Green Marathon saves a total of 41% CO2eq compared to its predecessor model.

The life cycle assessment was calculated on the basis of strict scientific criteria and in compliance with current standards. Schwalbe worked closely with both suppliers and pre-suppliers to collect the relevant data. The product carbon footprint (PCF) calculated with the life cycle assessment provides a key finding: the majority of emissions, 62% in total, are caused by raw materials.

Learn More about the Life Cycle Assessment

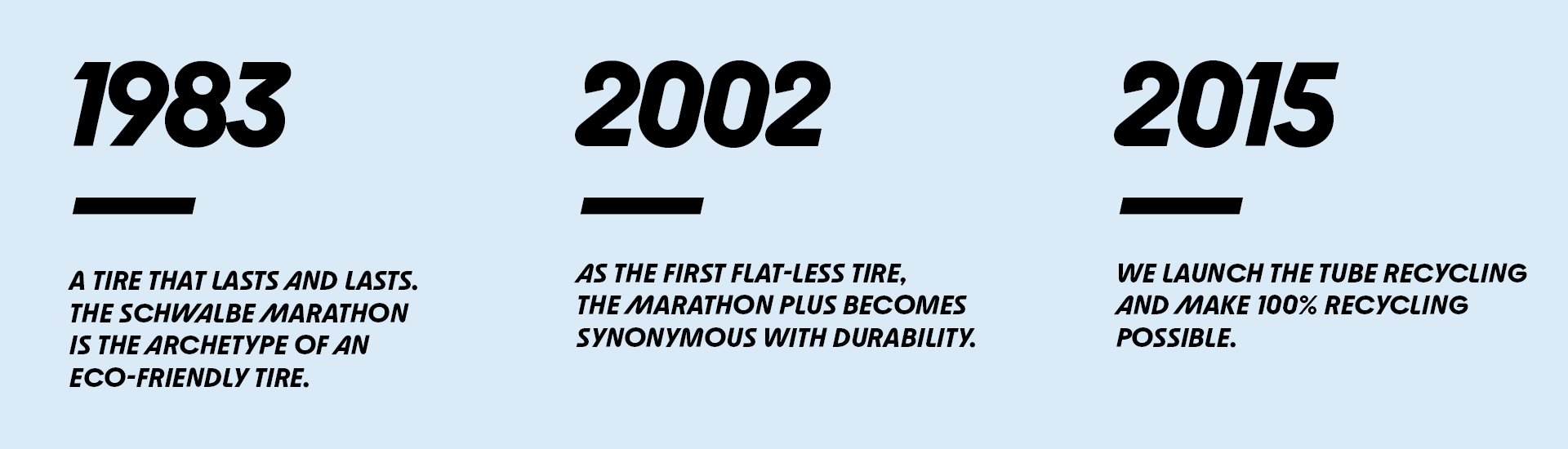

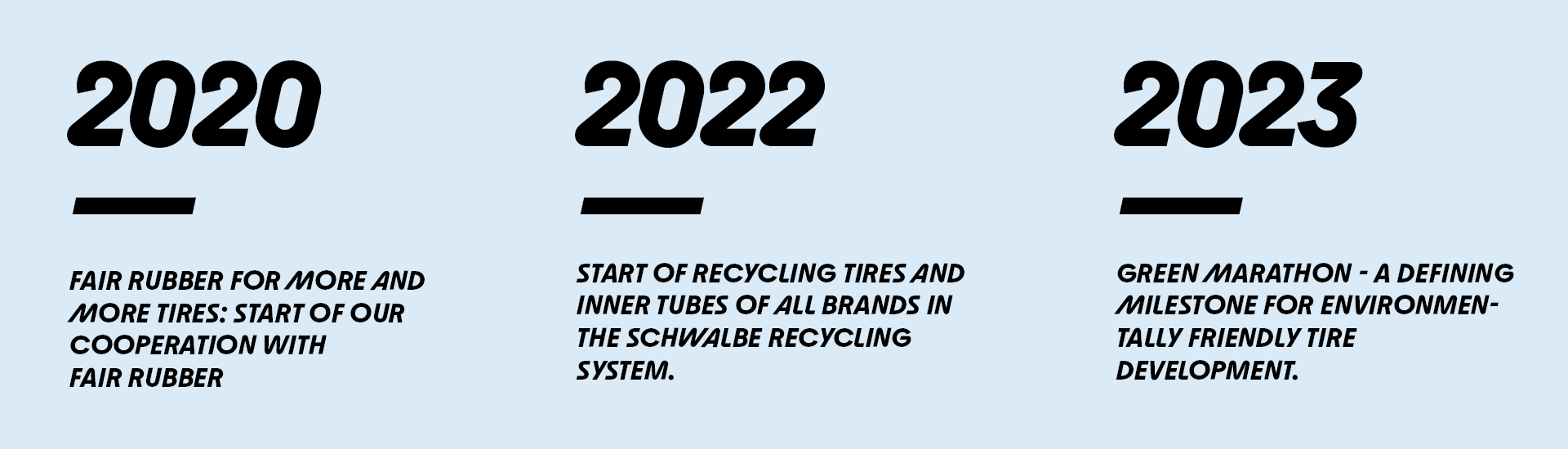

RESPONSIBILITY ISN’T A SPRINT, IT’S A MARATHON

NEW RESPONSIBILITY - SAME RELIABILITY

The new Green Marathon is superior to its predecessor in every way. Enjoy improved riding performance and all of the durability that you have come to expect from previous Marathon tires.

The pioneer in puncture protection, mileage and environmental friendliness

- Very good puncture protection thanks to GreenGuard

- Most environmentally friendly bicycle tire:

- Produced entirely from Fair Rubber

- Consists of 70% recycled or renewable materials:

- Among other things, the first and only tire with carbon black from recycled bicycle tires (rCB)

- 98% pollution-free

- Revised tread pattern optimizes rolling performance

- Recommended for bikes and e-bikes

THE PIONEER IN PUNCTURE PROTECTION, MILEAGE AND ENVIRONMENTAL FRIENDLINESS

Very good puncture protection thanks to GreenGuard

Most environmentally friendly bicycle tire:

- Produced entirely from Fair Rubber

- Consists of 80% recycled or renewable materials:

- Among other things, the first and only tire with carbon black from recycled bicycle tires (rCB)

- 99% pollution-free - Modern and sporty tread design

- Recommended for bikes and e-bikes

FAQ GREEN MARATHON

CO2 Savings / Recycling / Circular Ecnonmy

The abbreviation rCB stands for recovered carbon black. It is obtained from used tires. In the recycling process at our partner Pyrum Innovations, the tires are mechanically processed (shredded) and then recycled in a thermochemical process known as pyrolysis. One of the outputs is pyrolysis coke, which is then further processed into rCB. We have now used the rCB for the first time in the production of a new tire. The complete recycling process is explained here: https://www.schwalbe.com/recycling-system/

The rCB replaces 100% fossil-produced carbon black (vCB = virgin Carbon Black). The carbon black acts as a filler and reinforcing agent in the rubber compound. It influences the dynamic properties of the tire (abrasion, rolling resistance, wet grip) and is used for coloring.

The majority of virgin carbon black, or industrial carbon black, used worldwide is made by the so-called furnace process. In this process, fossil raw materials (crude oil and natural gas) are heated to temperatures well above 1000 degrees Celsius and then abruptly cooled. The product of this energy- and emission-intensive process is virgin carbon black.

100% of rCB used comes from our Schwalbe Recycling System. The exact "recipe" of our tires is a trade secret 😊

The rCB is extracted from used tires at our partner Pyrum Innovations in Germany and transported from there to Indonesia. The impact of the transport amounts to approx. 0.1kg CO2eq per kilogram rCB and thus only accounts for only approximately three percent of the total impact. Since the production of rCB emits 80% less CO2eq than conventional industrial carbon black, the reducing effects on the environmental impact are extremely positive.

It looks very positive overall. We are currently calculating a life cycle assessment of the entire recycling process as part of a doctoral thesis. As soon as it is ready, we will publish it. In principle, our transport routes are already more sustainable because we collect our products via bike retailers and not via the consumers themselves. Overall, all transport routes account for only a small percentage (three percent) compared to the chemical processes that we can avoid through our recycling. Nevertheless, we are continuously working to reduce and mitigate emissions wherever possible.

We have been producing our tires and inner tubes in close partnership with the South Korean family-owned company Hung-A in Southeast Asia since the Schwalbe brand was founded in 1973. This means that our factories are located where almost all necessary raw materials and materials are also extracted. Production in Germany would increase our transport emissions by a factor of three and a half (calculated on the basis of the emission factors of EN 16258 and the Global Logistics Emissions Council (GLEC) and reference to the ecoinvent 3.6 database, as of 2022). In addition, there would be transports to the manufacturers, most of whom also assemble in Asia. For the climate, a relocation of the production site would not pay off. At the same time, there are further advantages of our 50-year partnership with Hung-A: Not only do we know the people and processes very well, but we also have very high labor, human rights, environmental and quality standards at our production sites. There is a Schwalbe plant in both Vietnam and Indonesia. In addition, the know-how in the rubber industry in both countries is outstanding.

Raw materials

At the present time, the proportion of 70% recycled and renewable raw materials is the maximum possible. The fact that such a proportion is possible at all is due to our many years of research and development. Currently, we include the largest possible amount of recycled and renewable raw materials. Our goal is to further increase this proportion - but the range of "sustainable" materials currently available is not yet sufficient. We hope that research and technological developments will continue to progress in such a way that this will soon change.

The Green Marathon uses natural rubber, recycled rubber, recovered carbon black (rCB) from the Schwalbe Recycling System, recycled steel and silica from rice husk ash

The proportion of recycled components is around 20%, with a further 50% being renewable.

That was the tough nut to crack for us and something we achieved with the new Marathon- mainly thanks to extensive research and development and many years of experience. Basically, if we were to take back only Schwalbe products, the recycling percentage in our products would be even higher. The fact that we take back all brands means that we encounter different quality standards. Since our premium Schwalbe quality is an absolute priority for us, we determined the maximum possible percentage through countless tests, which guarantees that there is no loss in quality. This is currently around 20 percent for our tubes. However, we are naturally pursuing the goal of further increasing the proportion of recycled materials.

The Fair Rubber organisation can be compared to the Fair-Trade seal for coffee - only for natural rubber. Through our membership in Fair Rubber, we pay an additional €0.50 for every kilogram of rubber we buy from certified smallholders and tappers. This amounts to about one third of the current world market price. This financial support reaches and benefits the people directly at the beginning of our supply chain. They decide what is done with the premiums. Their living standards are improved, for example, by renovating local schools to give children access to education. The Fair Rubber certified natural rubber from Indonesia comes from so-called jungle plantations. Unlike monocultures, this type of plantation preserves the high biodiversity of the rainforest. So far, we are the only tire manufacturer that uses Fair Trade natural rubber in its products and helps the people directly with a financial premium.

Unfortunately, Fair Rubber's capacities in Indonesia are not yet at a level where this is possible. However, we have already increased the proportion of Fair Rubber enormously - this was the only way we could manufacture more tire models with it and also produce the Marathon. We are working very hard to increase capacity even further so that we can produce more and more products with fair rubber. And to support even more local people directly with the premium.

We have conducted intensive research over an extensive period of time to ensure that, despite the high proportion of recycled and renewable materials, we can still guarantee the durability for which the Marathon is known for. And we have made no compromises whatsoever in terms of riding characteristics either. In doing so, we have achieved something great, because recycled materials often are often of a lower quality than new materials. We are continuously developing recycling technologies together with our partners so that we can further increase the proportion of the material in other tires in the future - and the product quality remains just as high.

The Marathon remains the pioneer in terms of durability. It makes no compromises in terms of riding performance, grip and safety. Schwalbe's credo is always the combination of consistently high quality, maximum safety for the user and the maximum possible use of sustainable resources.

Product / Pollutant-free

Quite clearly: Yes! The new Marathon is just as suitable for cyclists as it is for e-bikers. We have continued to further develop our ADDIX Tour rubber compounds. As a result, the new Marathon is a fast-rolling and very grippy tire that does not require any sacrifices in terms of mileage and smooth rolling. This is not different than with the first generations of e-bike tires. Construction and puncture protection of the Marathon have already proven themselves hundreds of thousands of times in use on e-bikes.

A pollutant is a substance that can have a harmful effect on humans or the environment and the organisms living in it. Because the pollutants are trapped in the tire rubber, they do not pose a hazard. Since 2013, we have been reducing and replacing hazardous ingredients, wherever possible, with harmless alternatives. This is done according to the Cradle to Cradle® method.

We optimize our products not only in terms of their technical performance, but for many years now also from an ecological perspective using the Cradle to Cradle® method. Here, all ingredients are evaluated according to the so-called ABCX system. Raw materials rated A or B are harmless and their use is recommended. Raw materials rated C demonstrate low harmfulness, but their use in bicycle tires does not pose a risk. Only for the materials rated X ("X raw materials") is the search for alternatives recommended, because these substances can lead to problems under unfavorable circumstances.

"98% pollutant-free" does not mean that the remaining 2% are harmful. This is because the X raw materials include not only the harmful substances themselves, but also non-hazardous raw materials that contain small amounts of harmful substances. An example: The transparent plastic bottles frequently used to transport mineral water are made of PET (= polyethylene terephthalate). PET usually contains 0.02% antimony oxide, which must be added as a catalyst during production of the plastic. Antimony oxide is carcinogenic. However, in this case it is firmly enclosed in the plastic matrix and cannot escape during normal use of the bottle and endanger the consumer. However, if the bottle is burned, all the antimony oxide can be released. This hazard - although incineration of the bottles is not common - is nevertheless taken into account under the aspect of risk prevention, and the PET is given an "X" rating. Based on this understanding, even though Schwalbe tires contain up to 2% X raw materials, the proportion is even lower. The most important thing: These substances are firmly enclosed in the tire rubber and therefore cannot cause any damage.

Unfortunately, there is currently no alternative for these important ingredients that we can use in production. To eliminate the remaining 2% is one of our most important goals. That is why we are working and researching intensively on this - together with external experts and our partnerships in production and the supply chain.

Once alternative substances have been found, the hazardous ingredients will be replaced. Then the tire will be 100% pollutant-free. Intensive research is currently being carried out to achieve this.

We cannot make any statements about the substances used by our competitors. What we do know: Our collaboration with the EPEA consulting institute and the C2C project is unique in our industry. This has enabled us to continuously replace pollutants and to reach the current 98% pollutant-free benchmark for the first place.

With the Marathon, we have managed to develop the first mass-production tire that sets a completely new milestone in sustainability. Over the past few years, for example, we have succeeded bit by bit in replacing raw materials in our tires and increasing the proportion of pollutant-free materials to 98%. The knowledge we have gained from the development of this tire will certainly find its way into other Schwalbe products. We are working at full speed to procure the new, sustainable materials in even larger quantities. Then, step by step, more and more Schwalbe products will be produced using those materials. At the same time, we are conducting intensive research to gradually change our tire formulations.