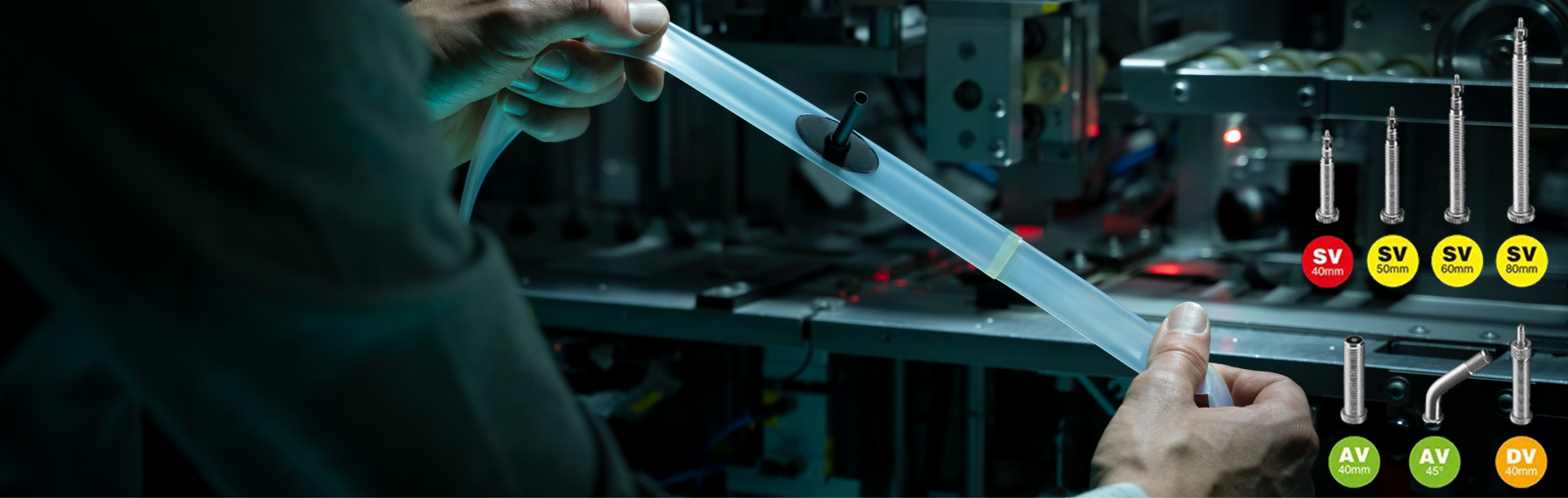

IS THIS STILL A BICYCLE TUBE?

During the development of Aerothan Tubes, we have explored new avenues

right from the beginning. The result was a high-end alternative to

conventional bicycle tubes. The next generation Aerothan tube

sets new standards for weight, puncture protection, riding characteristics, easy installation and

packing dimensions. Specifically made for

road bikes, MTBs and all-round purposes.

AEROTHAN TUBE

THE FACTS

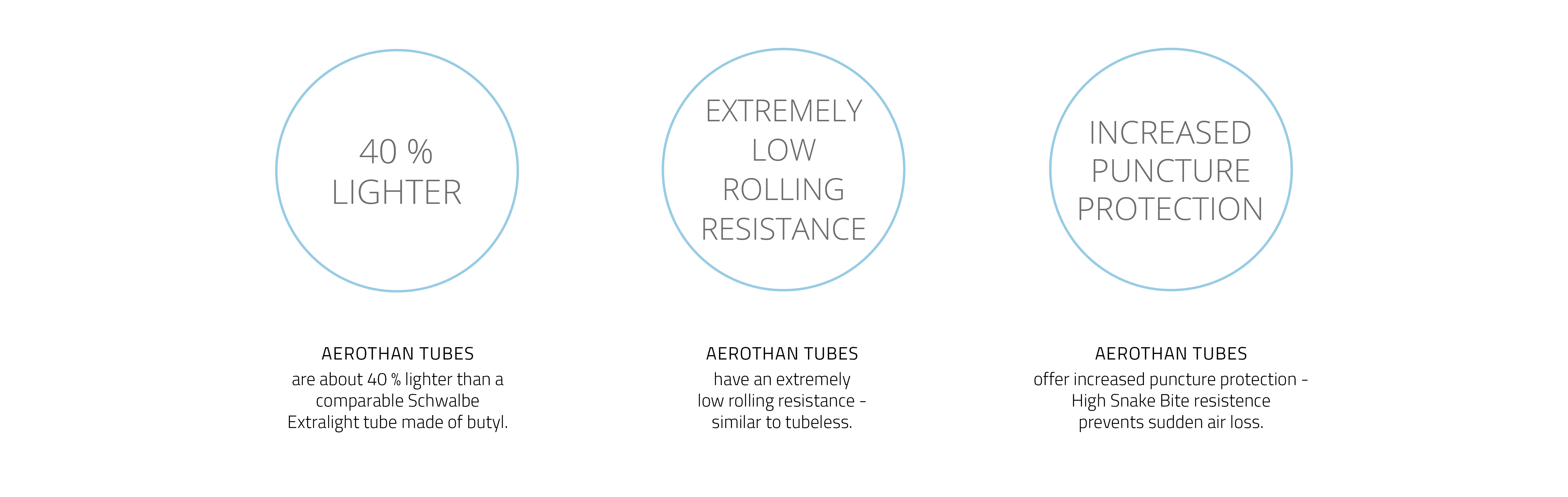

ADVANTAGES OF AEROTHAN TUBES

Fully light-weight, right to the valve - about 40% less weight than a comparable Schwalbe extra light tube

Puncture protection newly defined - the material itself prevents sudden air loss

Minimal rolling resistance - maximum riding dynamics

Extremely heat resistant - certified for rim brakes

A stable ride - even with low air pressures

Easy installation - without slipping or pinching

Made in Germany

100% recyclable

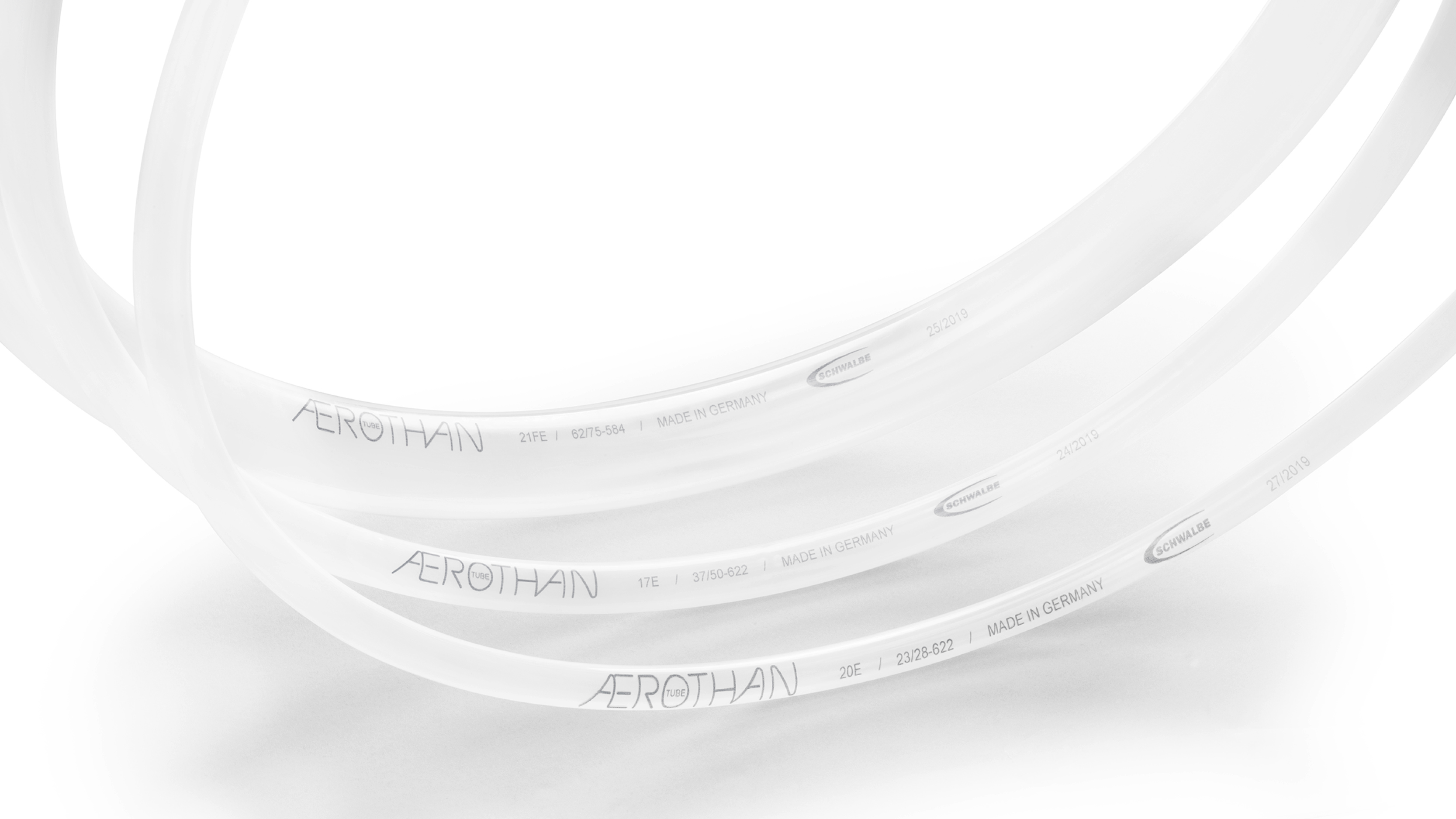

AEROTHAN IS 100% RECYCLABLE

Aerothan tubes consist of 100% thermoplastic polyurethane (TPU),

including the valve, and are therefore fully recyclable.

Like all Schwalbe tubes, Aerothan tubes

may be returned to Schwalbe at no cost

using the tube recycling programme. The material of used

tubes is recycled to make sealing or

insulation material.

DEVELOPMENT

AEROTHAN. THE WONDER MATERIAL FROM THE SCHWALBE INNOVATION HUB.

Schwalbe aims to offer the ideal product for every cyclist. In terms of high-end bicycle tubes, this is an exciting challenge. The engineers had to combine seemingly opposing features, lowest weight and highest puncture protection. This is a case for the Schwalbe innovation hub, where material compositions and construction principles are redesigned to make entirely new products. Developed in cooperation with BASF and with experts from the German plastic manufacturing industry, the Aerothan tube emerged to not only meet all the requirements of a high-end bicycle tube, but to exceed them.